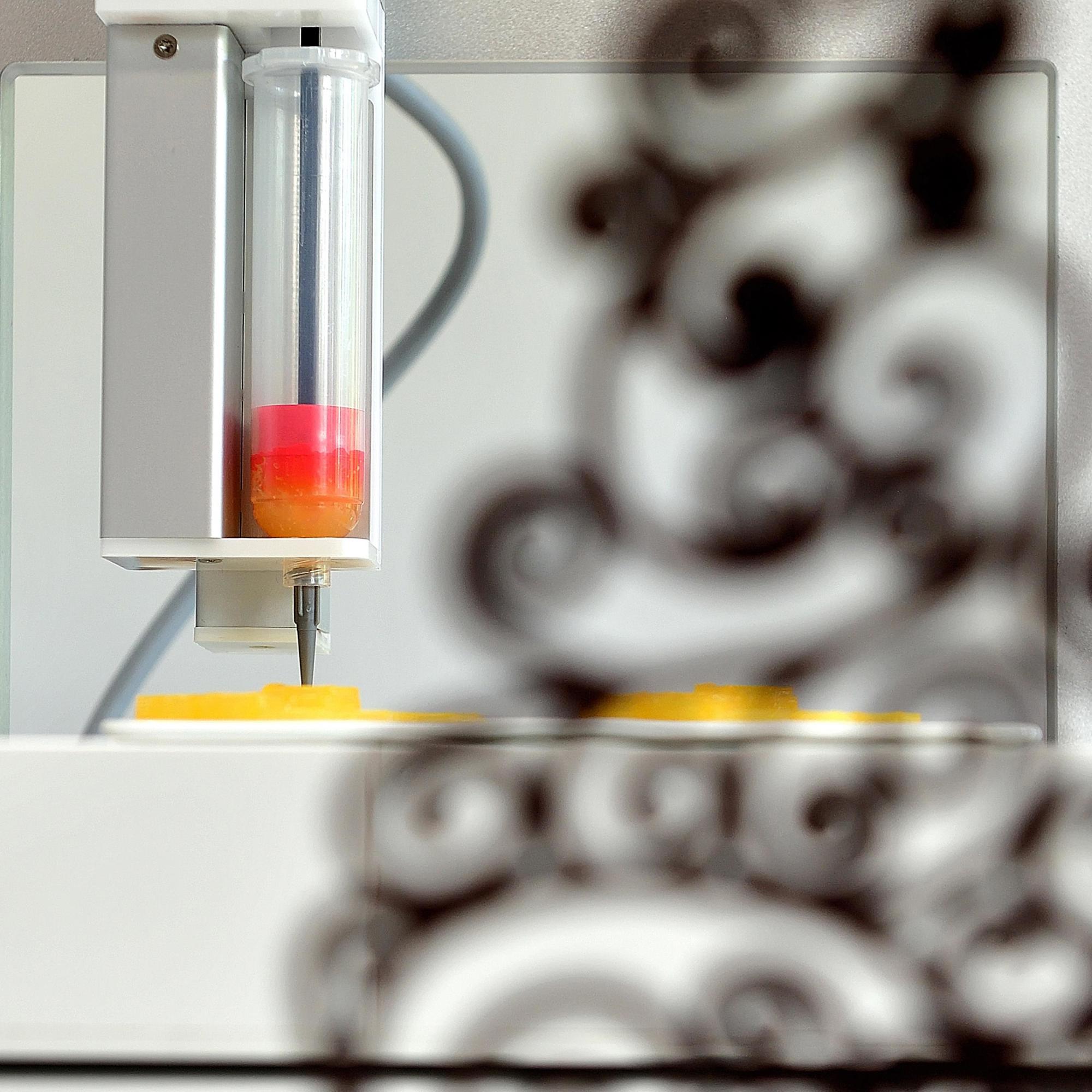

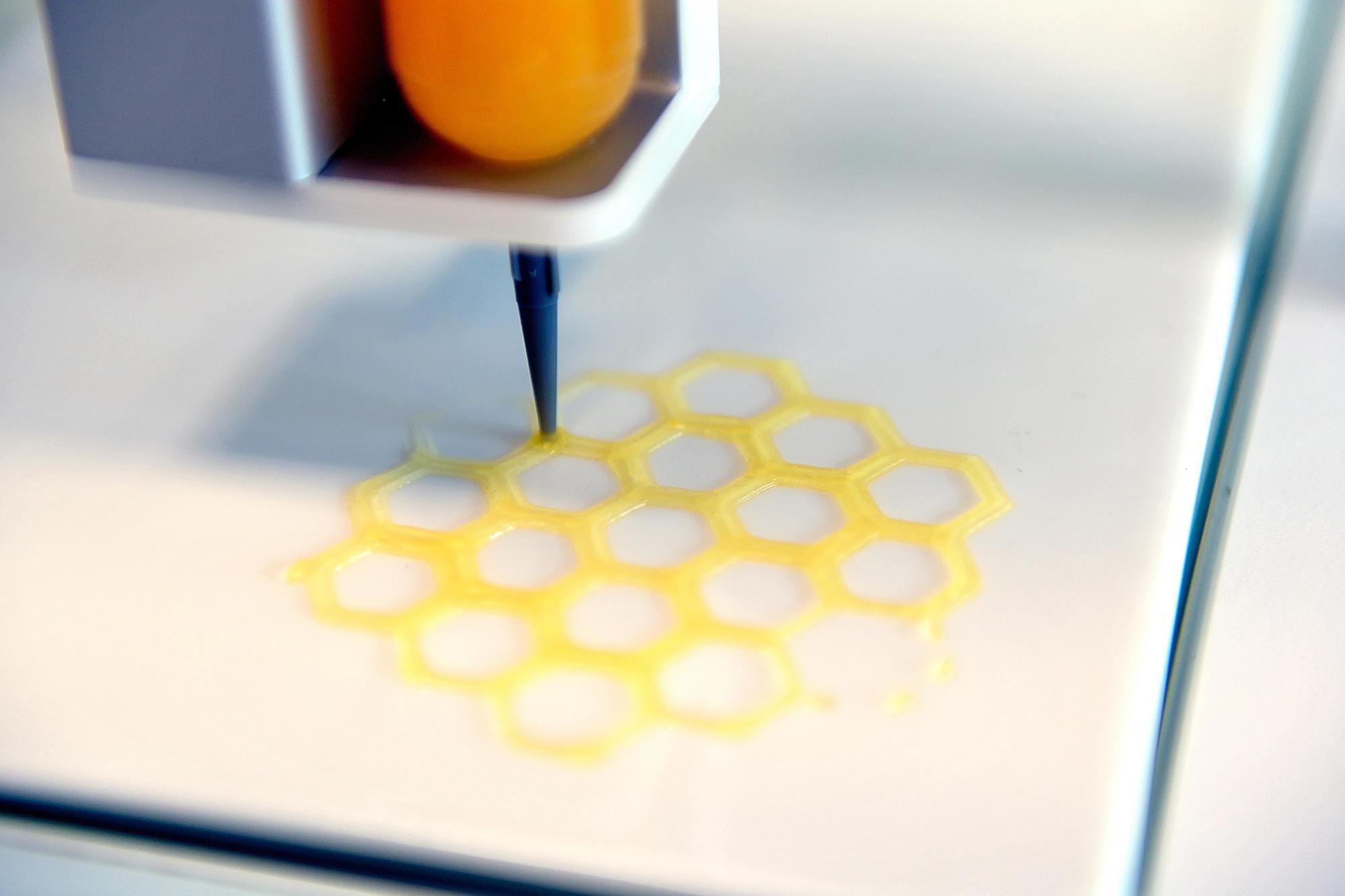

Fine chocolate lace, personalised butter designs, puréed vegetable structures: chefs can make all the figments of their imagination edible with byFlow's food printers. CEO Nina Hoff also hopes to convince the food industry of the advantages of these printers in order to change food preparation and how people experience food.

Nina Hoff, her brother Floris and father Frits are not great connoisseurs of culinary delights. Yet their 3D food printer is conquering hearts in the food industry. Capable of processing about fifty different ingredients, this printer can create special works of art, ranging from mascarpone cream to chocolate, and from puréed vegetables to beef.

At present, their 3D food printer is mainly intended for artistic designs that chefs can produce to impress the guests in their restaurants. However, they are about to scale up significantly. In the future, they want to deliver machines capable of making personalized products on an industrial scale - products that specifically take the customer’s allergies or personal preferences into account.

This really is a revolution in the food sector. Things might never have got this far if a mysterious mentor - a person with significant international experience who had taken early retirement - had not got involved with the company in 2016. Under the pretence of applying for a position as a sales executive, he paid an unsolicited visit to their business unit at the High Tech Campus in Eindhoven. Nina Hoff decided to interview him and accepted his offer of providing advice at no charge. She felt that a few grey hairs could hardly hurt in a team where the average age is just 25.

Since then, he has been coaching Nina and her team in all areas of the business. This adviser does not want to be named, but Nina would recommend every start-up to look for a mentor with his experience and wisdom. “Under his guidance, we discovered that we had to undergo a complete metamorphosis. So we switched to a 100% focus on printable foods.”

The story of byFlow starts in the FabLab in Maastricht - a publicly funded open lab for two-dimensional and three-dimensional design. Frits Hoff, the founding father of byFlow, was involved in 3D technology for the medical sector. He identified a need for custom-made prostheses. However, the 3D printers of the time could only process plastic. Frits enlisted the help of his son Floris (now CTO of byFlow), who was studying industrial product design in The Hague. Floris invented a new 3D printer with removable print heads, which was also capable of printing silicone or ceramics. As a publicity stunt, they decided to use Nutella as a raw material during an exhibition in Rome and were astounded by all the attention they attracted. Exhibitors queued up to print a Nutella star on a biscuit.

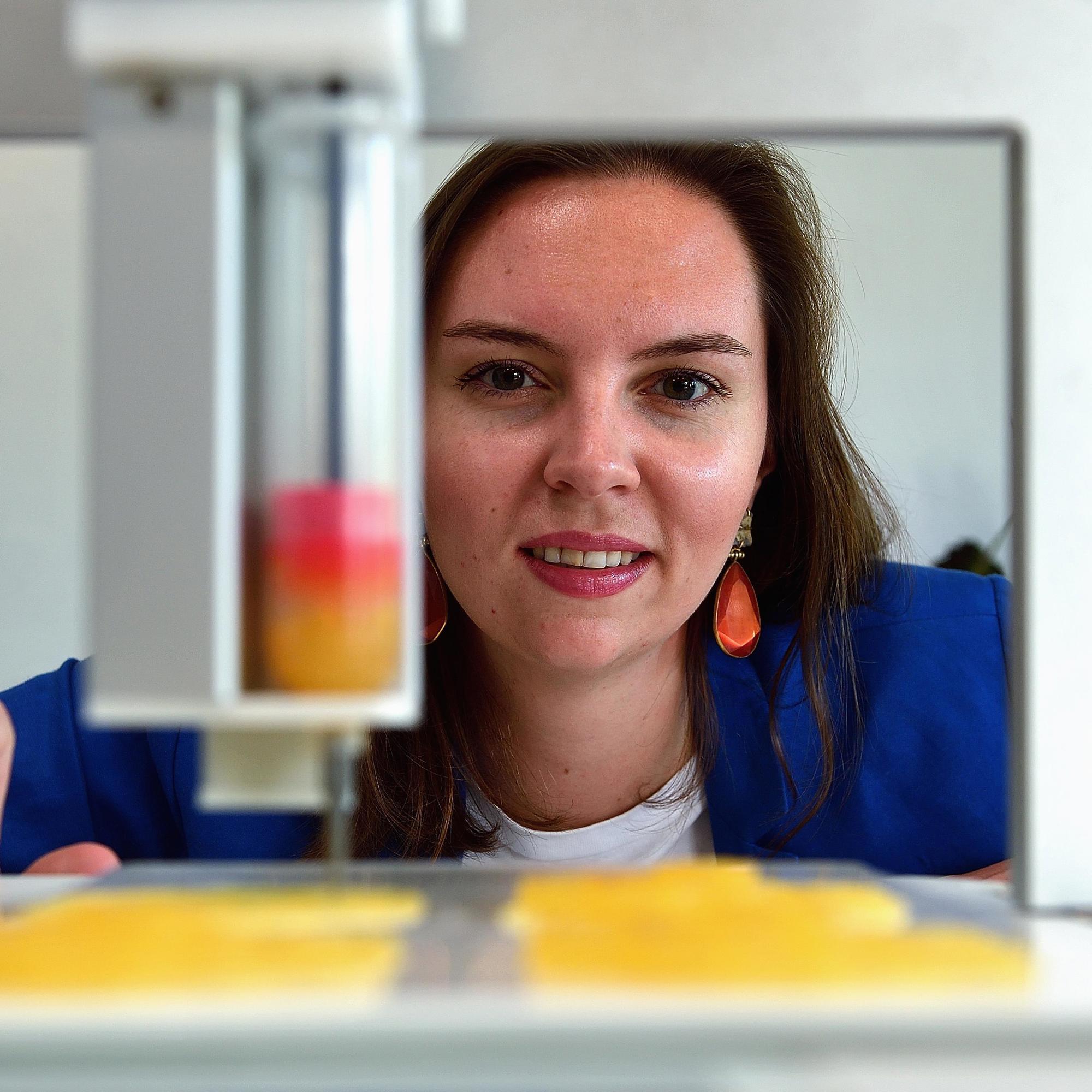

They felt they could start their own business based on this idea. So, in 2015, Frits and Floris founded byFlow. The word ‘Flow’ in the name refers to the liquid raw materials for the printer, and to Floris' former nickname: Flo. When Floris and his father were given the opportunity of participating in the Start-up Bootcamp accelerator programme a short time later, they were told to take someone on board to handle the business aspects. This is where Nina comes into the picture: at just 22 years of age, she became the public face of the new start-up based in Eindhoven. They made each other a solemn promise though: the family takes precedence over the business. “Nothing is more important than family," says Nina. “We are not prepared to give that up.”

There were a few sleepless nights during the first few years. In spite of tens of thousands of hits and likes on social media, hardly anybody bought their multi-material printers. “It didn’t take off initially”, Nina says. “People couldn’t get their heads around printing plastic first, followed by ceramics, without any loss of quality.”

In 2017, with the help of their senior coach, byFlow organised an internal ‘hackathon’ to investigate how to better publicise byFlow's vision, mission and future-oriented concept. The whole team analysed everything that had been posted about byFlow on social media and other channels. The conclusion was clear: printed foods were very popular, everything else was relatively low-interest. Nina was soon convinced that byFlow should focus entirely on edible printed products. Perfecting the concept further was pointless at this stage; the company needed to generate cash.

Deciding to focus on edible printed products led to heated argument within the family. Floris disagreed. After all, he hadn’t designed his high-tech equipment for mashed potatoes, had he? Frits was also less than enthusiastic. It was a totally unfamiliar world, for all of them.

In the end though, Nina managed to persuade her family. After careful thought, they decided to completely rebrand the company for the food sector in April 2017.

But they soon discovered that the food industry is a rather conservative sector that does not welcome outsiders. Trends like craftsmanship, natural foods and knowing where your food comes from seem to be at odds with their technology. Nina: “Printers are associated with ink, not healthy products. However, our products are completely natural. We occasionally use nuts to thicken the material, but that’s it: there are no other additives.”

So Frits started to talk to some of the big names in the restaurant world, such as Jan Smink, the chef at the Librije, who now owns his own restaurant in Wolvega. Jan Smink's curiosity was aroused and he travelled to Eindhoven the next day. “He was very taken with a vase made from butter,” Nina remembers. “I'd looked at it 67 times without really thinking about it, but he could see that it was very special. That was when I realised that we had something unique to kickstart the business.”

Partnerships and ambassadors helped them build bridges between the world of technology and food lovers. Other producers were also enthusiastic. The food printer can be used to create an attractive meal, with added vitamins, for people who suffer from chewing and swallowing problems. Cooks can instantly personalize products without having to use a mould. And the food printers help satisfy individual eating requirements, such as gluten-free, lactose-free and vegan food.

byFlow firmly believes that everybody will have a computer in the kitchen ten years from now. Nina: “Because of the shortage of kitchen staff, you can only cope if you allow technology to handle part of the workload for you. A food printer is just a way of putting the chef’s ideas on the plate. It will never replace the skill and talent required for preparing steak tartare with the right spices.”

Even so, the company did not grow as fast as they hoped. So they developed recipes together with star chefs and set up a collaboration with Verstegen, the leading Dutch supplier of herbs, spices and sauces. Chefs can view the recipes on their website and download them. The company also supports them in setting up their own 3D model. “The market does not yet fully understand what they can do with the printer in their business environment and how they can integrate it into their work processes. We help them make working with the printer less daunting.”

The next step is to integrate the printer in industrial food production processes. The printer takes 3 to 15 minutes to print the product, depending on the complexity of the design. The use of several printers controlled by one operator will drastically increase scale. These production units are sometimes referred to as ‘print farms’.

They have found various partners in Brabant that will help them achieve this growth. Machinery builder VDL in Eersel assembles the printer. “Finding the right companies is relatively easy in Brabant, and we can quickly scale up and down. We outsource our process, but obviously we have to train our partner's employees. That takes time and money, but quality comes first for byFlow. Furthermore, our entire supply network is located in Brabant. So we would have to think very hard before making any changes in that area.”

Nina is pleased with how she has developed personally: she used to be a recruiter in the healthcare sector and is now the CEO of this young company. She has become an ambassador for women working in the technology sector. “Technology is the most rewarding sector there is. You have an idea and you can get started right away. I am learning all the time here and enjoying the challenge of growing the company with the support of our team. Floris has entrusted his baby to me. He is the introverted thinker who had to let go of his creation so that it could develop. I am proud that he was able to do so.”

Fuelled by steady growth, byFlow intends to conquer the market and become the market leader in ‘industrial food printing’. “This field encourages you to be very creative because there’s no standard roadmap for 3D food processing,” Nina says. “We have opened up new sources of revenue by introducing food printing-related services, such as consultancy and acting as a keynote speaker at international congresses and workshops. We are a leading expert now and can capitalise more on that unique knowledge. And there are synergy effects as well, because these activities give us an increasingly accurate picture of where the market wants to go.” She is full of praise for their coach because he was instrumental in making sure they took the right decision. “We can always go to him with our concerns. So my advice to every start-up is: make sure you have the right people around you, people who understand your fears and concerns and who occasionally give you the little nudge you need when you are teetering on the brink of scaling up.”

You can copy the full text of this story for free at the touch of a button